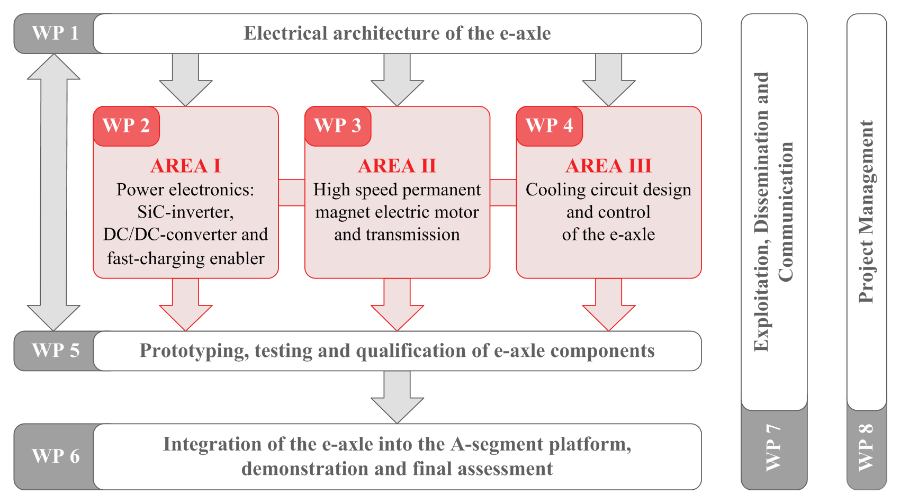

Objectives

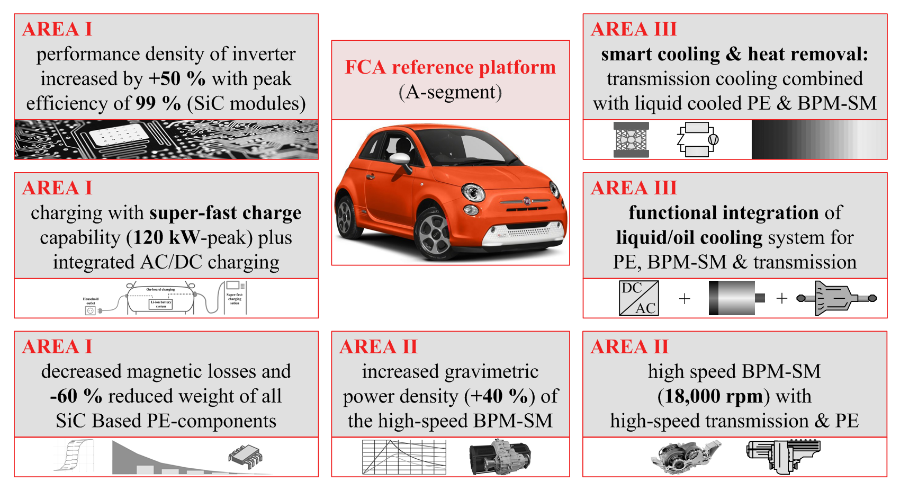

FITGEN aims at developing a functionally integrated e-axle ready for implementation in third generation electric vehicles. It is delivered at TRL and MRL 7 in all its components and demonstrated on an electric vehicle platform designed for the European market (A-segment reference platform). The e-axle is composed of a latest generation Buried-Permanent-Magnet Synchronous Machine, driven by a SiC-inverter and coupled with a high-speed transmission. It is complemented by a DC/DC-converter for high voltage operation of the motor in traction and for enabling super-fast charging of the 40 kWh battery (120 kW-peak) plus an integrated AC/DC on-board charger. The e-axle also includes a breakthrough cooling system which combines the water motor/inverter circuit with transmission oil. The FITGEN e-axle delivers significant advances over the 2018 State of the Art:

- 40 % increase of the power density of the e-motor, with operation up to 18,000 rpm

- 50 % increase of the power density of the inverter, thanks to the adoption of SiC-components

- affordable super-fast charge capability (120 kW-peak) enabled by the DC/DC-converter, integrated with single- or 3-phase AC/DC-charger

- increase of the electric driving range from 740 to 1,050 km (including 75 minutes of charging time) in real-world freeway driving with the use of auxiliaries

FITGEN aims to develop a functionally integrated e-axle ready for implementation in the third-generation electric vehicles (i.e., 2025 and beyond), with a TCO of -2.7% against the 2018 baseline and a production cost of the e-axle at 2,021 €/unit at 200,000 units/year production rate. It is designed to be brand-independent and to fit different segments and configurations of electric vehicles, including hybrids. The FITGEN consortium includes one car-maker and three automotive suppliers for motor, power electronics, and transmission, reproducing the complete supply chain of the e-axle. Their expertise is leveraged by the partnership with research institutions and academia, constituting an ideal setup for strengthening the competitiveness of the European automotive industry.